Wood Selection Process: Our Hands-On Approach

"What type of wood does Obra work with?" and "What is Obra's favorite type of wood?"

These are common questions, and the quick answer is: nearly any type of wood you can dream of.

While that may sound like a simple, too easy answer, the reality is that our sourcing and finishing possibilities are vast. Your perfect piece—whether for your custom kitchen, living space built-in, or individual piece of furniture —is the result of carefully balancing three critical factors: the wood species, the cut style, and the final finish.

When you start to explore the sheer number of options, it can feel overwhelming, or you might worry about making the "wrong" choice. Please don't worry. This is precisely where the Obra team and our expertise come in. We are here to guide you, make suggestions, hunt on your behalf, and ensure the final selection perfectly aligns with your vision.

The Journey to Your Perfect Plank: Hand Selection is Everything

This is the most crucial difference between Obra and a big box store: We do not choose from a short list, a catalog, or an online screen. We invest our time and energy into hand-selecting every single piece of wood for your project.

A Highly Personal Sourcing Process

We’ve cultivated strong, long-standing relationships with our trusted wood suppliers. For all Obra projects, Sergio, and sometimes Pato, Jorge, & Edgar, drive 2 hours from the shop in Mexico City to our preferred supplier in Cuernavaca, Mexico. Why make the long drive when there are closer options?

The reason is simple: Extensive selection and the hand-chosen process.

Our go-to supplier offers an extensive selection of wood from around the world. We’re talkin’ hundreds and hundreds of unique wood species (thousands and thousands of individual planks). We physically go through all the treasure troves, sifting through boards to find the absolute best fit.

This is a high-touch, human-centric part of our process. It goes beyond the look of the wood. Sergio and the Obra team are considering how each detail of the wood will be displayed in its final location of the project. We are checking the QUALITY, CONSISTENCY, SIZE, and unique GRAIN pattern of every single piece, but we are also analyzing critical production details: Will this board be structurally sound? Will the unique details of this grain be displayed properly after fabrication? Does this plank have a crack or thin section that would compromise the final plan? Does this client prefer consistent gain or a more organic pattern? We must consider all of these factors. Using a marker, we literally sign off with our initials on every piece we ultimately take home for your project.

This deep dive ensures we get the exact style, look, and quality required for your custom piece of furniture or cabinetry. We take this very seriously, because the raw material dictates the final product.

Part I: Wood Species – From Classic to Completely Unique

We have access to every standard, recognized wood species, and an abundance of alternatives that can make your project truly one-of-a-kind.

You name it, we can source it: Oak, Maple, Cherry, Walnut, Pine, Cedar, Fir, Mahogany, Poplar, Spruce, Redwood, and Rosewood.

But what about the species you may not be familiar with? We are particularly adept at sourcing unique options that can make your project shine:

Parota: Known for its distinct, bold grain with a two-toned color scheme—a medium brown heartwood with reddish or amber hues and a pale yellow complement. (We used Parota in Project Búho)

Tzalam: Used often in high-end furniture, its color ranges from chocolate brown to tan, sometimes featuring black stripes or a purplish/red tinge. This beautiful wood is favored by many Mexican designers, and we frequently use it for a variety of projects. (We used Tzalam for Chef Evan LeRoy's custom kitchen island, for our Obra Elements Beverage Stations , and in Project Este)

Breadnut (Mayan Nut): Similar to Tzalam in its workability and beautiful variations, but lighter in color. This wood is excellent for furniture and countertops. (We used Breadnut for Chef Kareem El-Ghayesh's custom kitchen island)

Chechen (Black Poisonwood): A prized wood for furniture, with color varying from amber, red, and orange to deep reddish-brown, often with contrasting dark stripes.

Chico Zapote (Sapodilla): A dense, durable hardwood known for its reddish-brown heartwood and cream-colored sapwood.

These are just a sliver (wink) of the vast and unique species we have access to that you likely won't find elsewhere. We have the experience and access to source truly unique, fresh species, ensuring your project stands out.

Part II: Cut Style – Defining the Look and Durability

The way the wood is cut reveals its character and impacts its function. We can customize the cut to achieve the look and durability you need.

Natural (Face Grain): The wide, flat side of a board, showcasing the tree's growth rings in beautiful "U" or "V" patterns. This is commonly used for visually appealing surfaces like tabletops and cabinet doors.

Edge Grain (Long Grain): Long, narrow strips of wood glued together with the parallel grain edges facing up. This creates a "striped" visual effect and a durable, stable surface, often used for countertops and robust display surfaces.

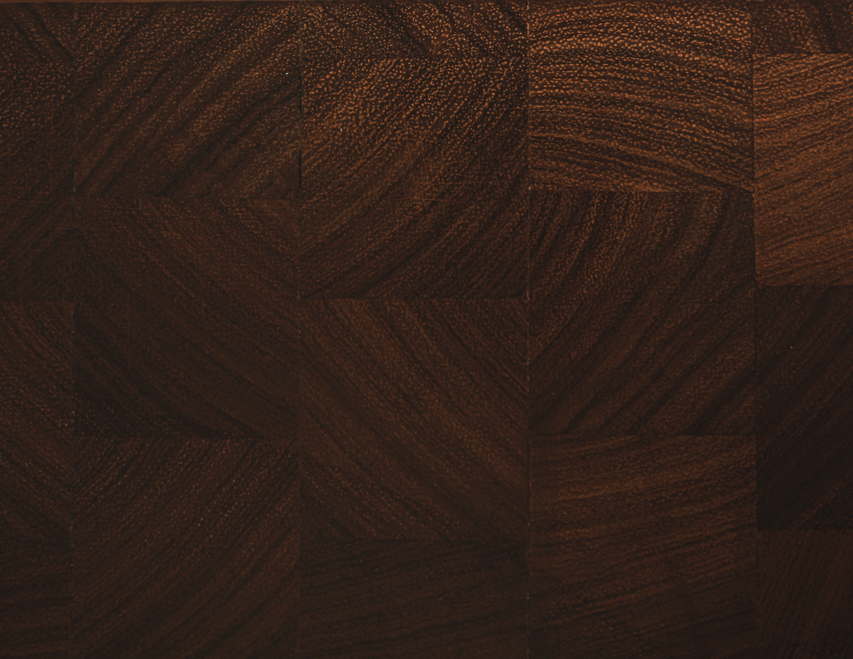

Butcher Block (End Grain): The vertical orientation of the wood grain creates a unique checkerboard or brick-like pattern. This construction is highly durable, "self-healing" (gentler on knife edges), and is the preferred choice for heavy chopping surfaces. (See our customizable cutting boards HERE)

Part III: The Finish – Coloring and Protecting Your Investment

Once the wood is selected and crafted, the particular finish protects it and brings its final color to life. We rely on industry leaders for consistency, quality, and durability across all our projects.

The Natural Wood Tone Look: Rubio Monocoat

We favor Rubio Monocoat, an industry-leading, 0% VOC (plant-based) hardwax oil finish. It forms a molecular bond with the wood fibers to protect the grain while enhancing its natural beauty.

Vast Options: With over 40 Rubio Monocoat “colors,” we can create numerous effects on the same piece of wood—from Natural to Midnight Sky or Cortado. You can take a peek at the color options here: [Rubio Monocoat]

Locally Sourced Quality: We love that Rubio Monocoat is headquartered right down the road in Spicewood, TX, connecting us with a trusted local source.

The Perfect Color Match: Benjamin Moore

For projects requiring a specific color, we rely on Benjamin Moore, a household name with over 3,500 colors and premium products. This is perfect for Obra, as we do installs across the USA and Mexico—making touchups and color matching consistent everywhere.

Color Math: We love to do what we call “color math.” We work with your references, existing rituals, and design aesthetic to extrapolate perfect color palettes and wood tones for your review.

Your Approval is Essential: The Samples Process

While we wish all our clients could drive down to Cuernavaca to hand-select the wood with Sergio & the team, we know that is difficult to coordinate!

Instead, we update you throughout the entire selection process and send you physical samples of the chosen wood with the finish applied. You get to review, feel, and approve the sample before we move forward with the production of your custom piece.

A Final Word: Respecting the Material, Honoring Your Vision

In closing, we hope this journey has illustrated that the wood selection process is an act of intention and dedication. We are not just selecting material; we are choosing the heart and soul of your future piece, recognizing that we are working with beautiful, organic, and truly unique material. For us, hand-selecting each plank—driving the miles, sifting through the options, and signing off on the perfect piece—is a commitment to quality and artistry. We enjoy educating our clients on all the possibilities, and we wholeheartedly invite you into the Obra hand-selection process. These decisions are not taken lightly; they are the foundation of your legacy project or piece, and we approach them with both expertise and respect.

Contact us via email Howdy@ObraProjects.com to chat about your next project or piece of furniture. Let’s make something amazing.