MDF & Solid Wood Construction

“I Want My Cabinets to be 100% Solid Wood.” No, You Don’t.

When clients hire Obra for custom remodels , upgrades, or furniture, we love discussing the beauty of wood species, cut style, and finish—just as we detailed in our previous blog post on [The Obra Wood Selection Process]. However, we often encounter one common request that needs a professional clarification: the desire for 100% solid wood cabinetry.

The truth is, most people are not familiar with modern, best-practice furniture construction. This may surprise some, but the notion that solid wood is always superior is outdated.

At Obra, we follow industry best practices by utilizing a hybrid approach: constructing the core structure of cabinetry with high-quality engineered materials, combined with wood veneer and solid wood elements where they perform best.

Before your brain explodes, let’s break down this equation and explain exactly why professional carpenters do this to create a product that is superior in stability, cost, and design.

Part I: The Core Structure—Why Engineered Wood Wins

The primary structural components of your cabinets—the flat panels, side walls, and shelving—need one thing above all: dimensional stability. This is where solid wood is inherently flawed, and high-quality MDF (Medium-Density Fiberboard) provides the necessary control.

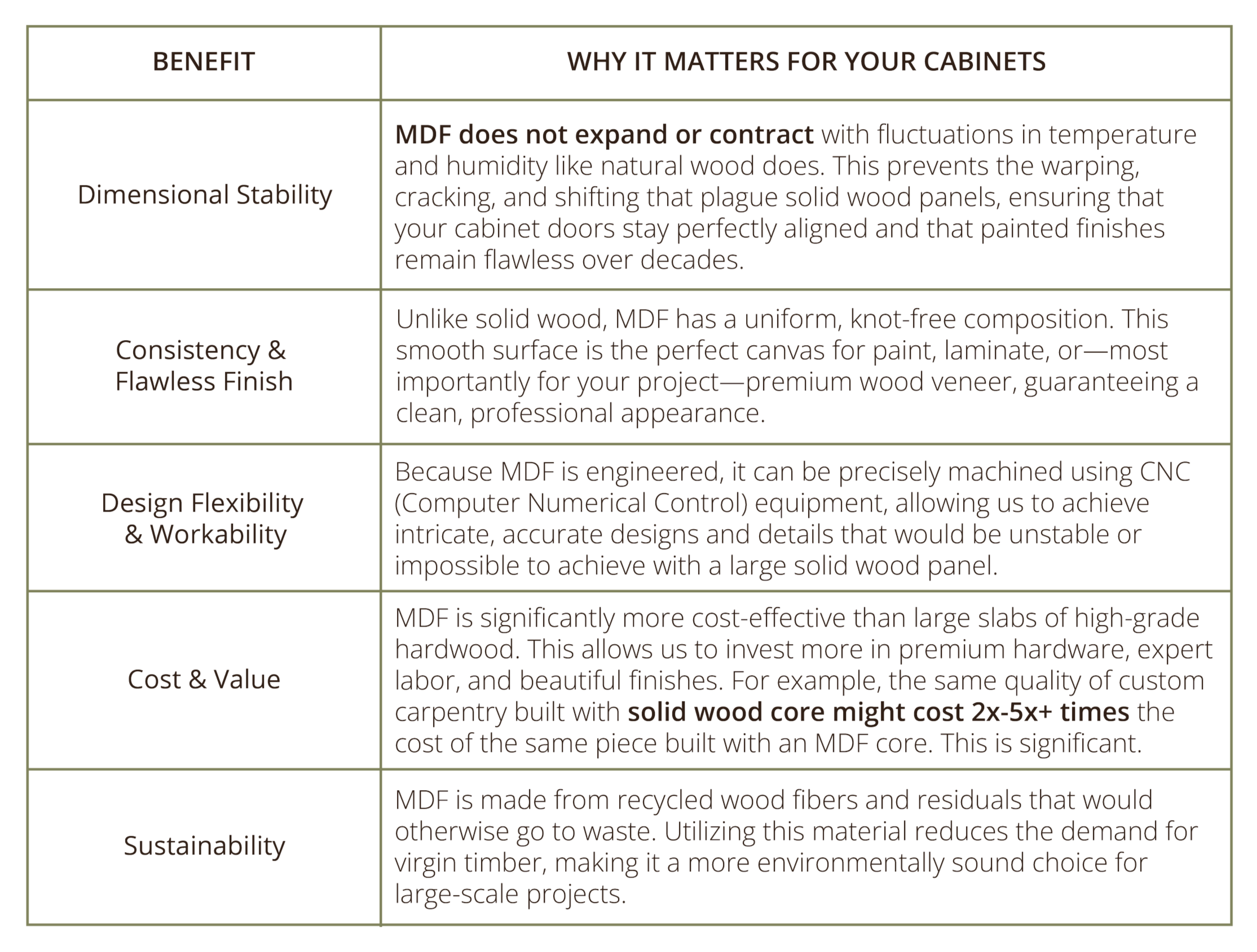

MDF is an engineered product made from compressed wood fibers, wax, and resin under high pressure. This standardized manufacturing process yields numerous benefits that solid wood cannot match for a cabinet box

The Unbeatable Benefits of High-Quality MDF

It is critical to note that for both MDF and veneer, there are varying levels of quality. We work exclusively with the highest-grade suppliers. This is not the cheap, flimsy MDF or veneer you might associate with big box furniture; it is of premium quality engineered for durability and longevity.

The Real Cost of 100% Solid Wood

While beautiful, using solid wood for the internal structure of large cabinet panels creates fundamental problems that compromise the finished product:

Movement and Cracking: Solid wood "breathes," expanding and shrinking with humidity. This puts immense stress on joints and painted surfaces, leading to cracks and warping over time.

Weight: Solid wood is extremely heavy, complicating installation, increasing labor and shipping costs significantly, and putting unnecessary strain on hinges and mounting hardware.

Lack of Control: The natural imperfections, grains, and limited widths of solid wood mean a lack of control over consistency and scale for large, flat panels.

The consensus among high-end carpenters is clear: using a stable core like MDF for the body of the cabinet is a modern best practice, not a budget shortcut.

Part II: Veneer—Actual Solid Wood

If MDF provides the necessary stability, wood veneer provides the unmatched beauty and character of natural wood. This is how we give you the look, texture, and prestige of solid wood without its structural drawbacks.

Defining Wood Veneer

Veneer is not cheap laminate. Wood veneer is a thin slice of actual solid wood that is carefully peeled or sliced from a high-quality log.

The process: Premium veneer logs are prepared in a highly controlled process (often steamed or soaked) and then sliced on a massive machine—sometimes horizontally, like a giant razor blade moving across the wood, or rotationally, like unwinding a roll of paper, or a giant pencil sharpener :) ✏️

This process yields several critical advantages:

Premium Aesthetic & Control: Veneer is sliced from the highest grade logs. The resulting sheets allow us to control the final look precisely. We can apply the panels so that grain patterns flow seamlessly across multiple cabinet faces for a consistent, formal look, or we can use specific cutting and matching techniques to create unique, organic patterns that match any aesthetic or design desire. We have far more control over the final aesthetic than we would with limited solid wood planks.

Sustainability: It allows us to utilize the natural beauty of one log across a much larger surface area, greatly increasing the sustainability of using rare species.

Obra’s Premium Veneer Selection Process

We apply the same commitment to material quality for veneer as we do for solid wood. Just as we hand-select solid wood planks and sign off on them, we apply a similar process to veneer. We visit the manufacturing facility to personally pick and choose exact sequences of veneer, ensuring the grain, color, and quality meet the design specifications for your unique project. This level of care guarantees the quality of your finished surface.

Part III: The Strategic Use of Solid Wood

So, where does 100% solid wood fit into Obra's production philosophy?

We use it strategically—where its natural strength, density, and ability to be reshaped shine:

Countertops and Butcher Blocks: Our iconic wooden countertops and customized cutting boards (See our customizable cutting boards [HERE]) are made from solid wood where the density and ability to be refinished are required.

Handles, Edges, and Details: For components that will be touched frequently, or that require intricate shaping and joinery, such as door handles, face frame edges, and trim details, solid wood is the superior choice for durability and repairability.

Door and Drawer Faces: We often use a hybrid panel approach for faces: a stable MDF center panel (to prevent movement) framed by a solid wood perimeter (for durability and joinery).

This strategic combination gives you the absolute best performance, a visually appealing final result, and a final product built on decades of modern carpentry best practices. We are not compromising; we are optimizing.

Your Next Step: Ask Us Anything

We believe that respecting the wood selection process means being transparent and educational. This approach—blending the stability of high-quality engineered core with the beauty of hand-selected solid wood and veneer—is the highest standard in modern custom carpentry.

We are always happy to answer any questions you might have, explore all the specific areas where solid wood can be used in your project, and we invite you to be part of the veneer selection process alongside our team.

Ready to see the possibilities for your next project?

Email Howdy@ObraProjects.com to discuss your next project or custom piece of furniture.